fedex corporation

FedEx Warehouse

This project included HVAC, plumbing and electrical design for a FedEx shipping warehouse near the Norfolk International Air Terminals in Virginia. Work included a solution for water mitigation, a new trench drain system, replacing light fixtures in conjunction with ceiling replacement, improved overall air quality and improvements to the heating system at the roll up doors.

Location: Norfolk, VA

Owner: FedEx Corporation

Type: Design

Budget: $11,440

FedEx Warehouse

Project Info Continued ….

Office Area

The existing office area was served with a Carrier split direct expansion system and condensing gas furnace. The indoor evaporator and gas furnace were matching equipment to the Carrier outdoor unit. The furnace portion of this unit was a condensing gas furnace with combustion air and flue gas extended through PVC piping to the roof. Fresh ventilation air was provided by the indoor unit through a roof cap.

The existing contract drawings indicated that the existing equipment was sized to provide 46.5 Mbh of cooling and 93 Mbh of heating with 1,680 CFM of supply air and 410 CFM of fresh ventilation air. We performed HVAC calculations on the Office area and indications were that the cooling load required 55.2 Mbh and the heating load 68.2 Mbh with 1,740 CFM supply air and 300 CFM of fresh ventilation air.

The existing roof mounted exhaust fan for the toilets was a CENTRI Master 115 volt, 1-phase, 0.1 hp motor requiring an exhaust flow rate of 500 CFM. Comparing the fresh ventilation air and exhaust air there was a negative amount of air flow of the office as compared to the warehouse area of 90 CFM. The existing toilets and Janitor’s closet were not modified and were calculated at an exhaust requirement of 225 CFM.

These changes provided a positive pressurization of the office space compared to the warehouse area of 75 CFM helping to avoid any unconditioned air entering the office area.

Warehouse Area

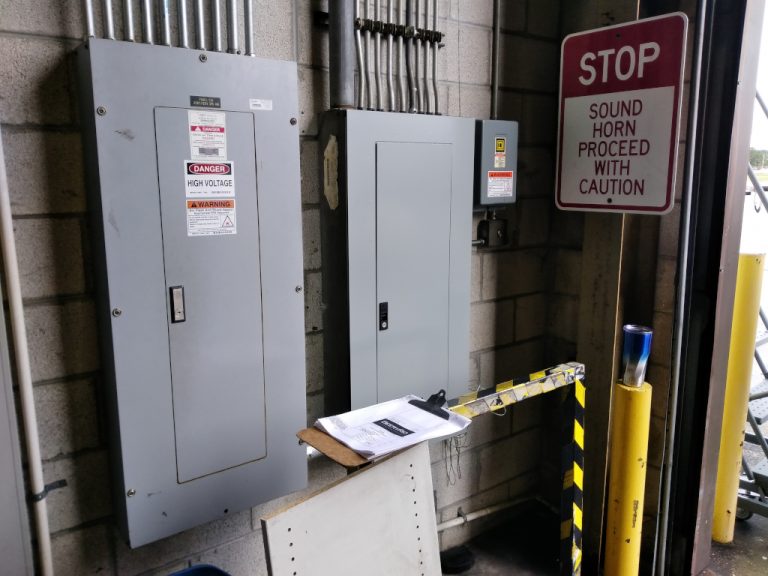

The warehouse area was heated and ventilated. One of the existing natural gas fired unit heaters was not working. At our site visit the unit was “tagged out” so it could not be operated because it was being worked on. Parts were on order and the unit heater fixed and put back into operation.

There was an existing Cambridge roof mounted heating and ventilating unit with manual override. This is a “make-up air” unit was interconnected to the Carbon Monoxide/Nitrogen Oxide detector system. The unit had a 4-way blow discharge plenum at the joist space producing an annoying air noise when the unit was operating. Reviewing the drawings verus the information of the name plate data on the Cambridge unit we found that the design air flow of the unit was for 4,200 CFM. The unit name plate data indicated that the air flow is 6,950 CFM. This significant difference would result in air noise in the plenum discharge that is only rated for 4,200 CFM. The discharge air plenum was changed to a device rated for higher air flow.

The remaining warehouse area was with ceiling type paddle fans, residential grade and diameter. The fans were removed and larger industrial type fans provided in their place.